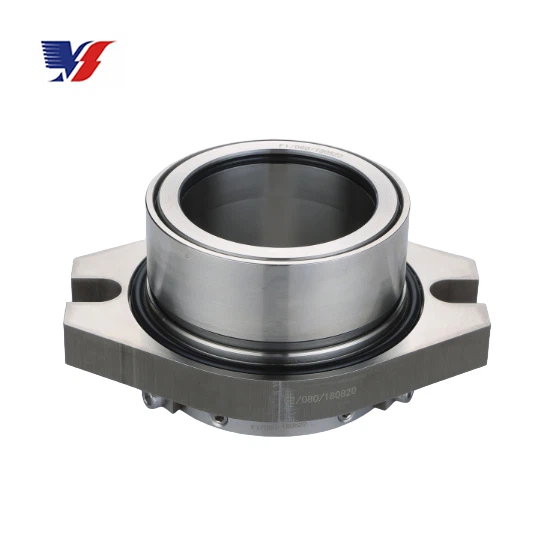

Single Cartridge Mechanical Seal

What Is Single Cartridge Mechanical Seal?

A single cartridge mechanical seal is an engineered device used to prevent fluid leakage from a rotating shaft interface, typically in pumps and mixers. It is referred to as 'single' because it has one seal face responsible for containing the pressure and maintaining the barrier between the process fluid and the external environment. This type of seal is housed in a cartridge unit, integrating all the components necessary for operation, including the primary sealing faces, secondary seals such as O-rings or gaskets, a gland plate, and often a sleeve that fits over the shaft.

Simplified installation: One of the primary benefits of single cartridge mechanical seals is their ease of installation. Since they come pre-assembled as a unit, there is no need to carefully assemble individual components. This not only saves time but also reduces the risk of errors during installation.

Reduced downtime: By simplifying the installation process, single cartridge mechanical seals help to minimize downtime during equipment maintenance or replacement. The simplified design also allows for quick and easy in-field repairs, ensuring that the machinery can be up and running again in a shorter amount of time.

Increased reliability: Single cartridge mechanical seals are designed to provide robust and reliable sealing performance. With fewer components and potential points of failure, the risk of leaks and equipment damage is significantly reduced. This enhances the overall reliability of the machinery, leading to improved productivity and cost savings.

Versatility and compatibility: These seals are compatible with a wide range of equipment, including pumps, mixers, agitators, and other rotating machinery. Their versatility allows for easy integration into various applications across different industries. Single cartridge mechanical seals can handle both low and high-pressure environments, making them suitable for a diverse range of operating conditions.

Minimal maintenance: Single cartridge mechanical seals require minimal maintenance, thanks to their robust design. The self-contained unit eliminates the need for regular component inspections and adjustments. Additionally, the use of high-quality materials ensures the longevity of the seal, reducing the frequency of replacements and associated downtime.

Balance type moving ring, simple installation, easy to use, excellent pump packing seal replacement products.

Cartridge Mechanical Seal Types

Balanced type double seal, double pressure balanced (the seal remains clo-sed in case of buffer fluid pressure failure or reverse pressu-re);

Buffer fluid system required; integrated circulation system eliminates the need for an additional circulating device.

Balanced type double seal, double pressure balanced (the seal remains clo-sed in case of buffer fluid pressure failure or reverse pressu-re);

Buffer fluid system required; integrated circulation system eliminates the need for an additional circulating device.

This product is suitable for flue gas desulfurization slurry circulating pump, supporting Australia Warman pump warman.

Structural features: single face mechanical seal. Easy installation. The utility model has the advantages of simple use, balanced type, arbitrary rotation direction, short internal working dimension, static ring compensation, multi spring external, and the spring is not contacted with the medium.

Eagleburgmann Mechanical Seals for Pumps

Single face

Unbalanced type

Arbitrary rotation

According with EN12756 (DIN24960) standard

KU7 series of wide application, strong interchangeability, tight sealing ring embedded, easy replacement. The push ring is jammed by the driving lug to prevent the spring from falling off.

The static ring can be limited, the spring travel is limited, so as to avoid excessive wear of the carbon ring.

This product is suitable for flue gas desulfurization slurry circulating pump

Single end mechanical seal, easy installation. The utility model has the advantages of simple use, balanced type, arbitrary rotation direction, short internal working dimension, static ring compensation, multi spring external, and the spring is not contacted with the medium.

Cartridge Type Mechanical Seal

The cartridge mechanical seal has been assembled into an aggregate, so it is more convenient, fast and reliable to be installed on the body, which is welcomed by domestic and foreign customers.

1) Heat shock stablity

2) Chemical corrosion-resistant

3) High temper-endure(up to 1650°)

4) Wearing/corrosion/oxidation resistant

5) Highly performance of mechanical strength

6) Cleaning or etching the hardest sub-surfaces

7) Used for grinding, lapping, and wire saw cutting as well as abrasive blasting

Independent

Arbitrary rotation

Balanced type

KHR series are special purpose seals, which are suitable for working conditions with particles but no external flushing and circulation. The main features are that the rotating non-compensating ring is directly installed next to the impeller, the sealing cavity is open, and the impeller and spring are protected.

Our factory

Gaodao Sealing Technology (Suzhou) Co., Ltd. was established in 2021 with a registered capital of 12 million yuan. It is a member unit of the China General Machinery Industry Association and has been successfully selected as one of the first batch of innovative and entrepreneurial leading talent enterprises in Gusu in 2022.

Advanced equipment

Our company has domestically advanced production, manufacturing and testing equipment, as well as professional technical personnel.

High quality

The company adopts an ERP management system, using scientific methods and data analysis to provide customers with high-quality products and stable delivery cycles.

Production market

In 2023, our company's total marketing revenue was 39.5 million yuan, providing strong support for the needs of major host factories, equipment factories, and end users nationwide.

24H online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

Oil and gas

In the oil and gas industry, single cartridge mechanical seals are utilized in pumps and compressors to ensure leak-free operations. They provide reliable sealing solutions for applications such as refining, petrochemical processing, offshore drilling, and pipeline transportation.

Chemical processing

Chemical plants rely on single cartridge mechanical seals to prevent the escape of hazardous or corrosive fluids. These seals find applications in pumps, mixers, and reactors, where they help maintain the integrity of the process and protect equipment from damage.

Power generation

Single cartridge mechanical seals are widely used in power generation facilities, including coal-fired, gas-fired, and nuclear power plants. They seal pumps and turbines, ensuring efficient and uninterrupted energy production.

Water and wastewater

Municipal water treatment plants and wastewater facilities utilize single cartridge mechanical seals in pumps and mixers. These seals help prevent contamination and leakage, ensuring the safety and efficiency of water and wastewater treatment processes.

Food and beverage

The food and beverage industry relies on single cartridge mechanical seals to maintain sanitary conditions during the processing and transportation of various liquids. These seals ensure that no contaminants or foreign substances enter the production line.

Components of Single Cartridge Mechanical Seal

Seal faces

At the heart of every mechanical seal are the seal faces. These are the surfaces that press against each other to prevent the escape of liquids or gases. In single cartridge mechanical seals, you'll find precisely engineered seal faces that maintain a tight and leak-free seal under varying conditions and pressures. These seal faces are often made from materials like silicon carbide, tungsten carbide, or carbon, depending on the specific application's requirements.

Gland plates

Gland plates are essential components that provide structural support to the seal faces. They help maintain the correct alignment and positioning of the seal faces, ensuring that they stay in contact with the right amount of force to prevent leakage. Gland plates are typically made from durable materials that can withstand the mechanical stresses and chemical exposures typical in industrial environments.

Springs and spring configurations

Springs are responsible for maintaining the necessary force on the seal faces to keep them in contact and effectively sealed. Single cartridge mechanical seals can feature various spring configurations, including single coil springs, multiple springs, and even wave springs. The choice of spring configuration depends on the specific sealing requirements and the operating conditions of the machinery.

Stationary and rotating components

In a single cartridge mechanical seal, you have stationary and rotating components. The stationary part typically attaches to the housing of the machinery, while the rotating part connects to the rotating shaft. These components work in tandem to create a dynamic seal that adapts to the rotational movement, ensuring a constant and reliable seal.

Secondary seals

Secondary seals are like backup plans. They act as an additional barrier to prevent leaks in case the primary seal encounters any issues. Secondary seals are often made of elastomers like viton or epdm and serve as an extra layer of protection, especially in situations where the primary seal faces May not be sufficient to prevent leaks.

Fluid characteristics: Knowledge of the fluid's properties, such as chemical compatibility, abrasive nature, and viscosity, can significantly influence seal material choice to ensure compatibility and longevity.

Pressure and temperature ranges: Seals must be able to withstand the full range of pressures and temperatures they will encounter in service without failing or degrading.

Shaft size and speed: Accurate measurements of shaft size and operating speed help in selecting the appropriately sized seal that can handle the kinetic energy produced during operation.

Seal material: The materials used for sealing faces and secondary components (like o-rings), must be appropriate for the service conditions to prevent premature wear or failure.

Environmental regulations: Compliance with local, national, or industry-specific environmental regulations concerning emissions must be considered to avoid fines or shutdowns.

Ease of installation: A single cartridge mechanical seal should allow for straightforward installation without requiring extensive equipment modifications or specialized tools.

Reliability requirements: Determining mean time between failures (MTBF) based on historical data can guide you toward seals known for their durability under similar operating conditions.

Cost-effectiveness: Evaluate not just the initial cost but also total life cycle costs including maintenance expenses, potential downtime, and replacement frequency.

The operation of a single cartridge mechanical seal revolves around the principle of creating a leak-proof interface between the rotating shaft and the stationary pump housing or casing. At the heart of this system are two primary sealing faces: one face attached to a rotating element (such as the shaft), and another face fixed to a stationary component (often referred to as the gland plate). These two faces are polished to very flat tolerances and are designed to slide against each other with minimal friction, forming an effective seal.

The rotation of the equipment's shaft causes the attached seal face to turn in unison. A drive mechanism within the cartridge ensures that there is sufficient force exerted on both seal faces, maintaining steady contact.

However, it is crucial that this contact pressure is controlled; too much force can lead accelerate wear and result in premature failure, while too little can cause fluid leakage.

To lubricate and cool these dynamic sealing interfaces, a fluid film often exists between them. This liquid barrier also helps reduce friction and heat generation – which are typical byproducts of mechanical seals subjected to rotary motion. Controlled pressure within this fluid boundary layers is managed through appropriate settings maintained by secondary sealing components like o-rings, gaskets or bellows within the seal structure that accommodate thermal expansion or vibrations without compromising the integrity of the primary seal.

How to Install The Single Cartridge Mechanical Seal

Pre-installation preparation involves inspecting equipment for damage, ensuring components are clean, and reviewing the manufacturer's guidelines for proper assembly. It's a crucial step to prevent issues and ensure a successful seal installation.

Inspect the equipment: Before installing a single cartridge mechanical seal, thoroughly inspect the equipment to ensure it is in good working condition. Any damage or misalignment should be addressed before proceeding.

Clean the components: Make sure all components are clean and free from contaminants. This includes the seal faces, gland plates, and springs. Cleanliness is crucial for an effective seal.

Review the manual: Always refer to the manufacturer's installation manual for specific guidance on your seal. Each seal May have unique requirements and instructions.

Proper installation procedures ensure that single cartridge mechanical seals are correctly aligned, lubricated, and compressed for an effective seal. Installing them as per manufacturer guidelines is vital for reliable performance.

Correct orientation: Ensure that you install the seal with the correct orientation. The stationary part should connect to the equipment's housing, while the rotating part attaches to the shaft.

Apply lubrication: Use the recommended lubricants to ease the installation process and protect the seal faces during initial operation.

Set proper compression: Adjust the compression of the seal faces as per the manufacturer's guidelines. Proper compression is essential for an effective seal.

Check alignment: Verify that the seal components are correctly aligned. Misalignment can lead to premature wear and seal failure.

Our Factory

Gaodao Sealing Technology (Suzhou) Co., Ltd. was established in 2021 with a registered capital of 12 million yuan. It is a member unit of the China General Machinery Industry Association and has been successfully selected as one of the first batch of innovative and entrepreneurial leading talent enterprises in Gusu in 2022.

The company currently has nearly 70 employees, including 12 technical engineers and 5 university and industry consultants. The company adopts an ERP management system, using scientific methods and data analysis to provide customers with high-quality products and stable delivery cycles. Having advanced domestic production, manufacturing, testing equipment, and professional technical personnel.

FAQ

Hot Tags: single cartridge mechanical seal, China single cartridge mechanical seal manufacturers, suppliers, factory, Bellows Mechanical, Mechanical Seal For Agitator, cartridge mechanical seal, Metal Mechanical Seal, Seal Types Of Agitator, technical improvement mechanical seal

You Might Also Like

Send Inquiry